Window to the Magical World

Beer is one of the oldest drinks known to humans. It has been with us since the birth of our civilization. Beer was used to heal, beer was used to pay, and finally beer was simply drunk and enjoyed. Like everything that is truly great, over the years it has become surrounded by various myths and tall tales.

Technology and materials have improved with the development of science and technology, but the basic process of brewing beer has not changed over the centuries. Water, malt, hops and yeast are used, just like hundreds of years ago. Today I will try to tell you how this magical drink is actually made, without myths and tall tales.

Water is one of the main components of this process – beer is almost 90% water. And most of the myths about beer are connected with water. In fact, it was water that formed the creation of the beers brewed in a specific area. In those ancient times there were no water treatment systems, so they brewed it with what they had on hand. In the Czech Republic, for example, the water is very soft. That’s why for the Czech beers, you need soft water. Stouts require harder water. And the water in London is 10(!) times harder than in the Czech Republic. Of course, there are other components that affect the taste of the beer and therefore, all serious breweries have a water treatment station that deals with water quality.

Some breweries even purify water completely by reverse osmosis and then add the necessary microelements to it.

The next component of our favorite beer is malt. Malt is grain that has been germinated and roasted with a special technology. Most brewing malt comes from barley, but wheat and sometimes rye are also widely used.

How is malt prepared process work? – The harvested barley is sorted according to its content and soaked. After the future malt has absorbed moisture, the remaining water is drained and the grain is dried and roasted. Most of the grain consists of starch and enzymes. During germination, the enzymes, having received moisture, “wake up” and start “working”. This process is stopped by roasting, immersing the enzymes in a half-asleep condition – they are kind of dormant, but ready to wake up at any moment and start working.

The roasting process mainly determines the flavor and performance of the grain. The base grain for brewing beer is only lightly roasted to stop the germination process of the grain. Base malt tastes soft and sweet, converts almost completely to sugar during the brewing process. By adjusting the roasting process, we are change malt properties. Special kinds of malt can to add caramel or even chocolate flavor to beer. There are kinds of malt that add to beer taste of honey, coffee or dried fruit. Malt can regulate the flavor, the aroma of the beer and even the beautiful foam in our glass.

Another very important ingredient for brewing beer is hops. It did not begin to be used in beer until the twelfth century, although it had been known long before that. In Russian the word “hoppy” is mistakenly associated with alcohol. In fact, hops have a different function – they give beer bitterness and aroma. Hops are also a powerful natural anti-bactericide and protect beer.

This plant, or rather its cone-shaped flowers, contains acids and aromatic oils. It is these that are used in brewing. In recent years, many unusual varieties of hops have been developed. For example, there are hops which give beer the taste and aroma of exotic fruits, different flowers…

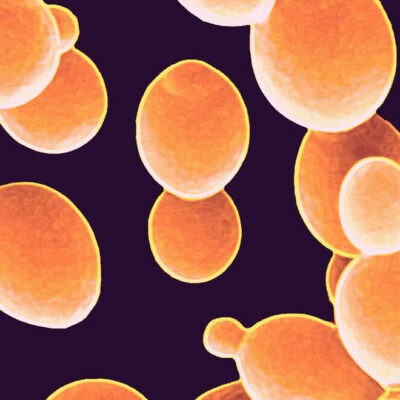

And the last important component of any beer is beer yeast. Yeast is a single-celled microorganism. They are everywhere, even in the air. Until a pure culture of the yeast was developed, brewers used yeast fungi in the environment to spontaneously ferment beer. The results varied accordingly. If the beer was good, they thanked God; if not, they blamed the devil.

Cultured beer yeast is usually divided into two large groups: top-fermenting yeast and bottom-fermenting yeast. The former works at a higher temperature and floats upwards during fermentation. They are used to make ales, stouts and other top-fermenting beers. Lower fermentation yeasts, respectively, settle down during fermentation and are used in lagers. It is the yeast that produces the alcohol and carbon dioxide in the beer.

I talked about the basic ingredients needed to make beer. How to make a good beer with them – in the second part.